点击蓝字

关

注

我

们

导语:

在250kPa高压与冻干循环下,Technetics的充气密封件如何实现从3万次到50万次疲劳寿命的飞跃?答案藏在这项全球领先的耐久性分析技术中。

ENDURICA VALUE ADD FOR TECHNETICS: ① Winning innovation ② Right-the-first-time engineering for demanding environments ③ Readiness for Digital Twin applications | ENDURICA为Technetics带来的价值: ① 制胜创新 ② 针对严苛环境的“一次成功”工程 ③ 支持数字孪生应用 |

ENDURICA 用户聚焦

ENDURICA USER SPOTLIGHT

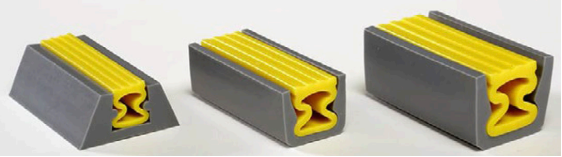

Inflatable sealing technology is used in critical applications, from anchoring drill rigs to the seabed to gas loading systems, pipeline welding, and watertight doors/panels. | 充气密封技术用于关键应用场景,从海底钻机锚固到气体装载系统、管道焊接以及水密门/面板。 |

Capable of adapting to varying environmental and service conditions, inflatable seals can be expanded and contracted pneumatically or hydraulically to accommodate changes in components that move in relation to one another, and those that are frequently connected and disconnected. | 充气密封件能够适应多变的环境和服务条件,通过气动或液压方式膨胀和收缩,以适应相互移动的组件以及频繁连接和断开的部件。 |

| |

Inside the world’s most demanding applications, you’ll find trusted engineered solutions from Technetics Group. | 在全球要求最严苛的应用中,Technetics集团提供值得信赖的工程解决方案。 |

Along with global manufacturing locations, their experience is vast, and their solutions comprehensive. | 凭借全球化的生产基地,他们拥有丰富的经验与全面的解决方案。 |

From the advanced R&D center to their company-wide commitment to relentless testing and precision, they are committed to improving safety and optimizing performance for each of their clients. | 从先进的研发中心到全公司对严格测试与精度的不懈追求,他们致力于为每位客户提升安全性与优化性能。 |

| |

Technetics Group is one of the world’s best-known sealing and component design manufacturing businesses delivering highly engineered seal designs and critical component solutions. | Technetics集团是全球知名的密封与部件设计制造企业,提供高度工程化的密封设计和关键部件解决方案。 |

With innovative manufacturing and responsive technical expertise, their engineering leadership is respected and admired across the globe. | 凭借创新制造与敏捷的技术专长,他们的工程领导力在全球备受尊重与赞誉。 |

| |

ELASTOMERIC PRODUCTS INCLUDE: ① CEFIL’AIR® Inflatable Seals ② Extruded Profiles ③ Plate Seals ④ Molded Seals | 弹性体产品包括: ① CEFIL’AIR® 充气密封件 ② 挤出型材 ③ 平板密封件 ④ 模压密封件 |

客户耐久性要求

CLIENT DURABILITY REQUIREMENT

Technetics uses workflow from Endurica to predict the life of CEFIL’AIR inflatable seals which provide a flexible connection between a ship’s turret and the riser buoy of an offshore oil and gas rig. | Technetics采用Endurica的工作流程预测CEFIL’AIR充气密封件的寿命,该密封件用于连接船舶转塔与海上油气平台的立管浮筒。 |

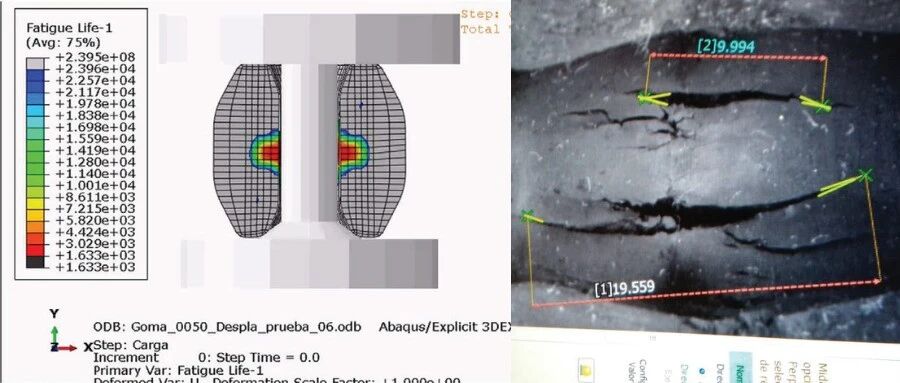

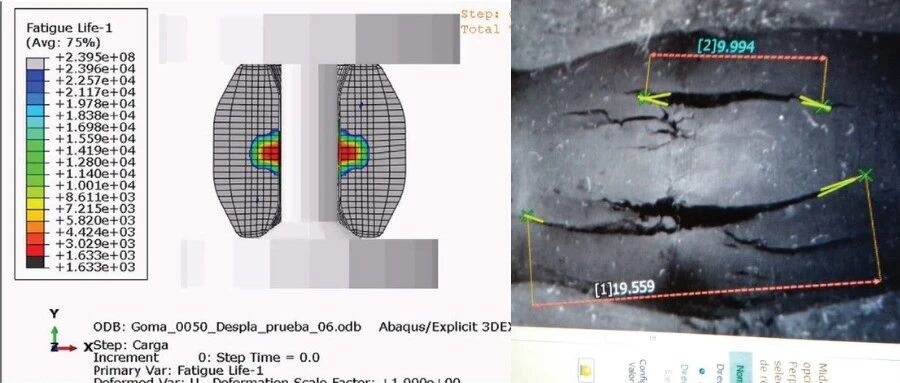

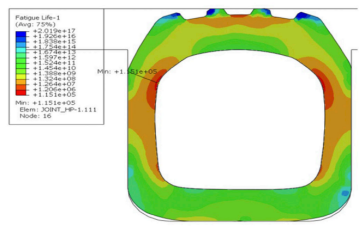

Endurica CL™ is used to predict the initiation of a crack with propagation criteria and to study different seal extrusion profiles. | Endurica CL™用于预测裂纹萌生(基于扩展准则)并研究不同密封挤出型材。 |

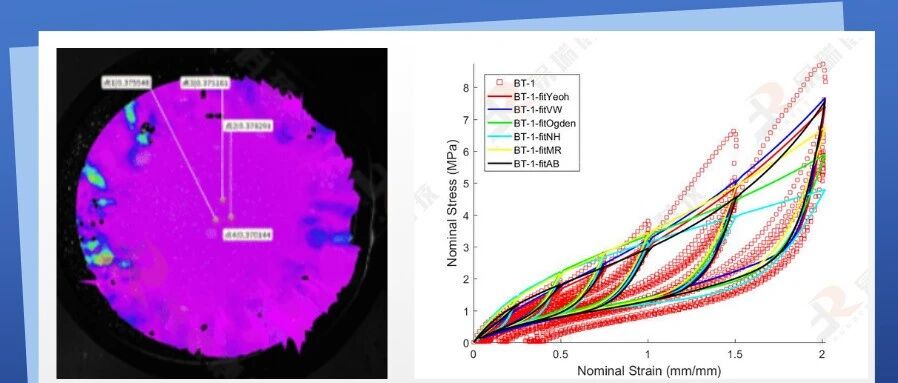

Non-linear material models (Ogden Hyperelasticity) were considered for FEA analysis through ABAQUS combined with ENDURICA for fatigue life prediction. | 通过ABAQUS结合ENDURICA进行有限元分析时,采用了非线性材料模型(Ogden超弹性模型)以预测疲劳寿命。 |

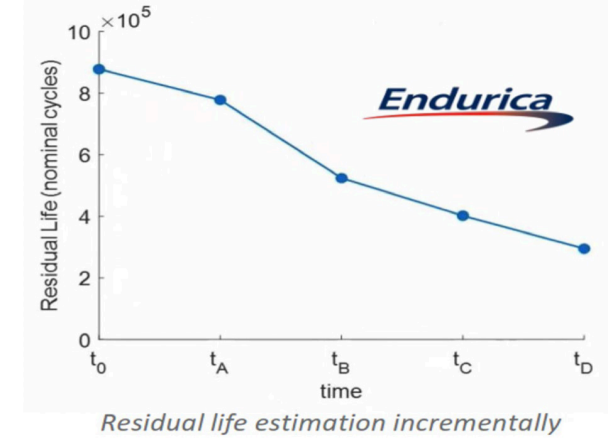

Prediction of residual life for the seal is estimated with the help Endurica DT™ software solutions. | 密封件的剩余寿命预测通过Endurica DT™软件解决方案实现。 |

| |

The seals operate at up to 250 kPa inflation pressure, with a mean temperature of 10°C. | 密封件的工作压力高达250 kPa,平均温度为10°C。 |

The seals must function for a specified number of years while enduring lyophilizer cycles without cracking. | 密封件需在指定年限内正常工作,承受冻干机循环而不开裂。 |

| |

Analysis with Endurica CL™ and DT™ helped Technetics to design better inflatable seals by considering the large strain behavior, leveraging the parameterized modeling techniques, and fatigue analysis. | 通过Endurica CL™和DT™的分析,Technetics优化了充气密封件设计,综合考虑大应变行为、参数化建模技术和疲劳分析。 |

Prediction of fatigue life has helped engineers at Technetics to accelerate the design life cycle for the best in class products to maintain the market leading position. | 疲劳寿命预测帮助Technetics工程师加速设计周期,打造顶尖产品以保持市场领先地位。 |

Additionally, fatigue analysis with Endurica has allowed Technetics to respond quickly and effectively to customer needs and to ensure delivery of “right the first time” solutions. | 此外,通过Endurica的疲劳分析,Technetics能够快速高效响应客户需求,确保提供“一次成功”的解决方案。 |

| |

“In optimizing a geometry to extend the fatigue life of a product I ran a few iterations of inner-cavity geometries and found one specific geometry with Endurica that achieved 500,000 cycles to failure in contrast to the 30,000 I had before. | “在优化几何形状以延长产品疲劳寿命时,我通过Endurica对内部空腔几何形状进行了多次迭代,最终找到一种特定几何形状,其失效周期从原来的30,000次提升至500,000次。 |

It’s more than a 10-time improvement and that’s really significant.These concrete numbers are really powerful in helping us and our customers to make good decisions.” | 这一超过10倍的改进意义重大。这些具体数据极具说服力,能有效帮助我们的客户做出明智决策。” |

——François Rouillard, R&D Mechanical Engineer, Maestral Sealing Laboratory, Technetics | ——François Rouillard,Technetics集团Maestral密封实验室研发机械工程师 |

END

想获取您的密封件定制寿命分析方案?

立即联系技术专家!

联系方式 | 易瑞博科技(天津)有限公司 |

电话:022-28750273 | |

邮箱:business@e-rubber.com.cn | |

可提供服务:橡胶材料非线性力学性能测试、橡胶疲劳耐久性测试、橡胶构件疲劳耐久性分析 |

—关注我们,了解更多精彩—

B站

视频号